The manufacturing industry is evolving at an unprecedented pace, driven by the integration of tool clamping innovations and the rise of intelligent automation systems like the universal robot gripper. Together, these technologies are redefining productivity, precision, and flexibility across diverse industries—from automotive and aerospace to electronics and healthcare. The push for smart factories under Industry 4.0 has accelerated the adoption of automated solutions that not only enhance efficiency but also reduce downtime, minimize errors, and ensure seamless workflow.

This guide explores how tool clamping and universal robot gripper systems are reshaping the automation landscape, their applications across industries, and the transformative future they promise for manufacturing processes worldwide.

Understanding Tool Clamping in Modern Manufacturing

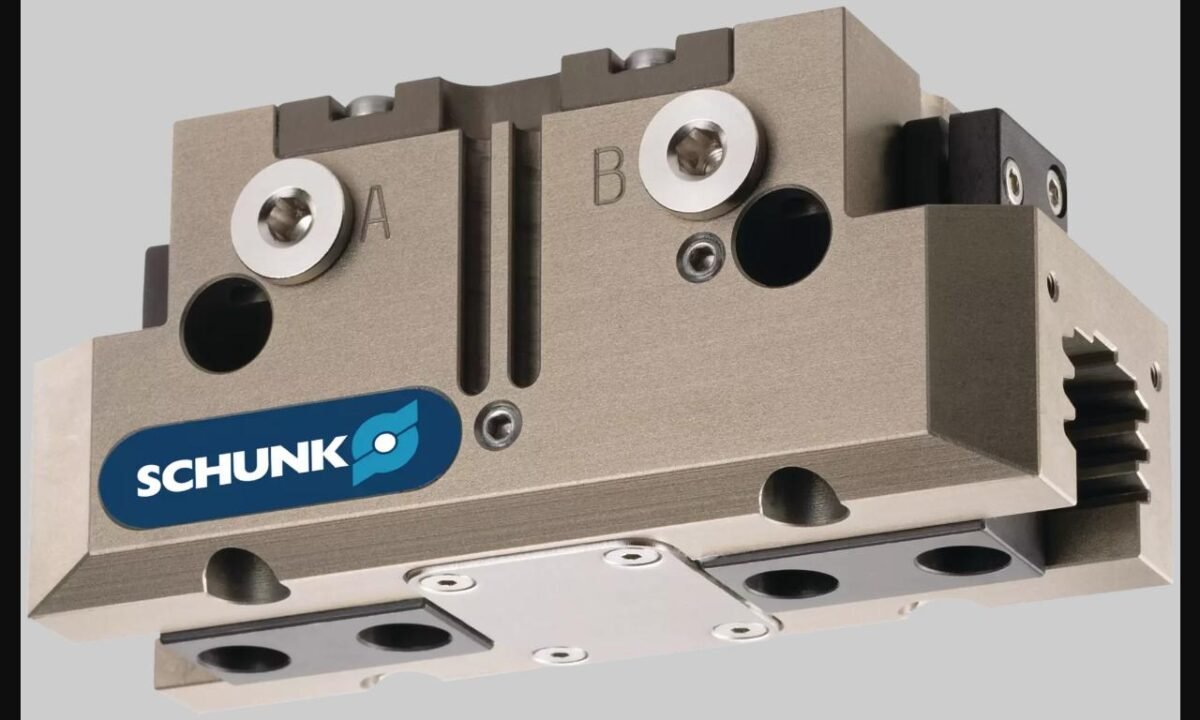

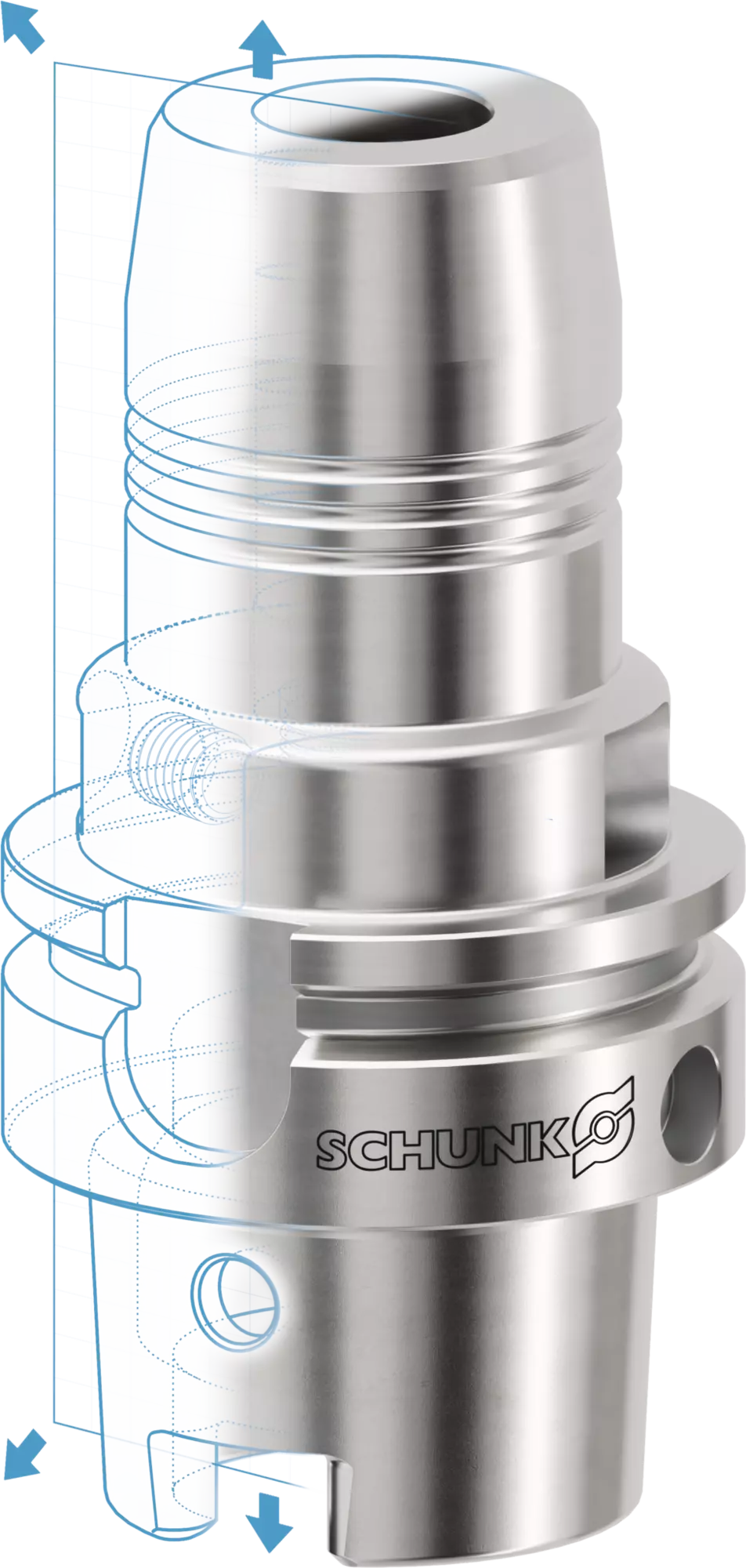

At its core, tool clamping is the process of securely holding cutting tools, machining components, or workpieces in place during operation. Traditional clamping methods relied heavily on manual setups, which were prone to inconsistencies, operator errors, and reduced efficiency. In contrast, advanced clamping systems now leverage mechatronic, hydraulic, and magnetic technologies to ensure accuracy, repeatability, and quick tool changes.

Modern tool clamping offers several benefits:

- High precision – Ensures tools remain stable, reducing vibration and enhancing machining quality.

- Reduced downtime – Automatic tool change systems allow faster production cycles.

- Operator safety – Eliminates manual handling, lowering the risk of workplace accidents.

- Longevity of equipment – Stable clamping minimizes wear and tear on both tools and machines.

In today’s competitive manufacturing world, precision and uptime are vital, making tool clamping an indispensable part of automated production lines.

The Rise of Universal Robot Gripper Technology

The universal robot gripper is another revolutionary innovation reshaping the automation sector. Unlike traditional grippers designed for specific tasks, universal grippers offer adaptability and flexibility, enabling robots to handle a variety of objects with minimal reconfiguration.

There are several types of universal robot gripper technologies, including:

- Mechanical grippers – Mimic the action of human fingers for reliable gripping.

- Vacuum grippers – Use suction to handle delicate or lightweight items.

- Soft robotic grippers – Made with flexible materials, allowing safe handling of irregular or fragile objects.

- Magnetic grippers – Efficiently lift metallic components without physical pressure.

This versatility makes universal grippers an excellent choice for industries where product shapes, sizes, and materials vary frequently.

Tool Clamping and Universal Robot Gripper: A Synergistic Combination

When integrated, tool clamping and universal robot gripper technologies create a dynamic synergy in manufacturing environments. Automated tool changers paired with adaptable grippers allow robots to switch between tasks seamlessly, reducing production bottlenecks.

For example, in a machining center:

Tool clamping secures the cutting tool with precision.

The universal robot gripper positions and holds the workpiece.

Once machining is complete, the gripper can transfer the part to the next stage of production.

This synchronized workflow not only boosts efficiency but also ensures consistent product quality and faster time-to-market.

Industry Applications

The integration of tool clamping and universal robot gripper systems has found applications across multiple industries:

Automotive Manufacturing

From engine components to body panels, precise machining and assembly are critical. Tool clamping ensures accuracy in cutting and shaping, while universal robot gripper technology allows for seamless handling of complex parts, reducing reliance on manual labor.

Aerospace Industry

Aircraft parts demand extremely tight tolerances. Tool stability through advanced tool clamping is crucial for safety and reliability. Grippers, especially soft and adaptive ones, safely transport delicate materials like composite panels without damage.

Electronics and Semiconductors

Handling micro-components requires both precision and delicacy. Universal robot grippers with soft gripping technology minimize the risk of product damage, while tool clamping ensures accuracy during circuit board drilling or assembly processes.

Healthcare and Medical Devices

The medical sector benefits greatly from robotic automation. Surgical instruments and prosthetics require highly accurate machining through reliable tool clamping. Meanwhile, robotic grippers ensure sterile and damage-free handling of sensitive components.

General Manufacturing

In factories producing consumer goods or industrial equipment, the combination of tool clamping and universal robot gripper enhances flexibility by allowing quick adaptation to varying product designs and assembly needs.

The Role of Automation Technology in Industry 4.0

The integration of tool clamping and universal robot gripper systems aligns perfectly with the principles of Industry 4.0. Smart factories rely on real-time data, interconnected devices, and automated systems to improve decision-making and efficiency.

Key contributions of these technologies include:

- Predictive maintenance – Sensors embedded in clamping devices monitor performance and signal when maintenance is needed.

- Flexibility in production – Universal grippers handle multiple product types, supporting high-mix, low-volume manufacturing.

- Reduced operational costs – Automation minimizes manual errors and downtime, resulting in cost savings.

- Scalability – Systems can be easily upgraded or expanded to meet growing production demands.

Future Prospects of Tool Clamping and Universal Robot Grippers

The future of tool clamping and universal robot gripper technology lies in further innovation and integration. Some key trends include:

- AI-Driven Systems – Machine learning will enable adaptive gripping and self-adjusting clamping systems, enhancing efficiency without human intervention.

- Collaborative Robots (Cobots) – Grippers and clamps designed for cobots will allow safer human-robot collaboration in factories.

- Miniaturization – Smaller, more precise clamping systems and grippers will cater to industries like electronics and medical devices.

- Sustainability – Energy-efficient automation systems will reduce the carbon footprint of manufacturing processes.

As innovation advances, next-generation solutions such as the Schunk EGU 60 will continue to set benchmarks for precision, flexibility, and reliability in smart manufacturing environments.

Challenges and Considerations

Despite their benefits, adopting tool clamping and universal robot gripper technologies comes with challenges:

- Initial Investment Costs – Advanced systems require substantial upfront capital.

- Integration Complexity – Compatibility with existing machinery may demand customized solutions.

- Skilled Workforce – Operators and technicians must be trained to manage, monitor, and maintain automated systems.

Addressing these challenges requires a balance between technological innovation, cost efficiency, and workforce development.

Conclusion

The fusion of tool clamping and universal robot gripper technologies is revolutionizing automation, driving unparalleled efficiency, safety, and precision across industries. From automotive to healthcare, these solutions empower businesses to meet the growing demands of modern production while paving the way for smart factories of the future.

As manufacturers embrace Industry 4.0, adopting advanced clamping systems and versatile grippers will no longer be optional but essential for staying competitive. Companies leading this transformation are setting new standards in productivity and innovation.

One such leader is Schunk, a trusted name in clamping technology and robotic automation solutions, providing industries worldwide with cutting-edge systems that exemplify the future of manufacturing.