Introduction

In today’s fast-paced industrial environment, manufacturing efficiency has become one of the most critical factors for success. Across the UAE and GCC, industries are under increasing pressure to reduce costs, enhance quality, and meet rising demand for infrastructure and construction projects. One technology playing a vital role in this transformation is the Plastic Pipe Extrusion Line.

Pipe extrusion systems are not only helping manufacturers produce pipes at scale but are also redefining how factories operate by improving productivity, reducing waste, and ensuring higher product consistency. With applications spanning water supply, plumbing, oil and gas, and agriculture, extrusion lines are now considered indispensable in the region’s industrial landscape. This article explores how pipe extrusion improves manufacturing efficiency and why decision-makers in the UAE should invest in advanced extrusion technologies.

What Are Pipe Extrusion Lines?

Understanding the Extrusion Process

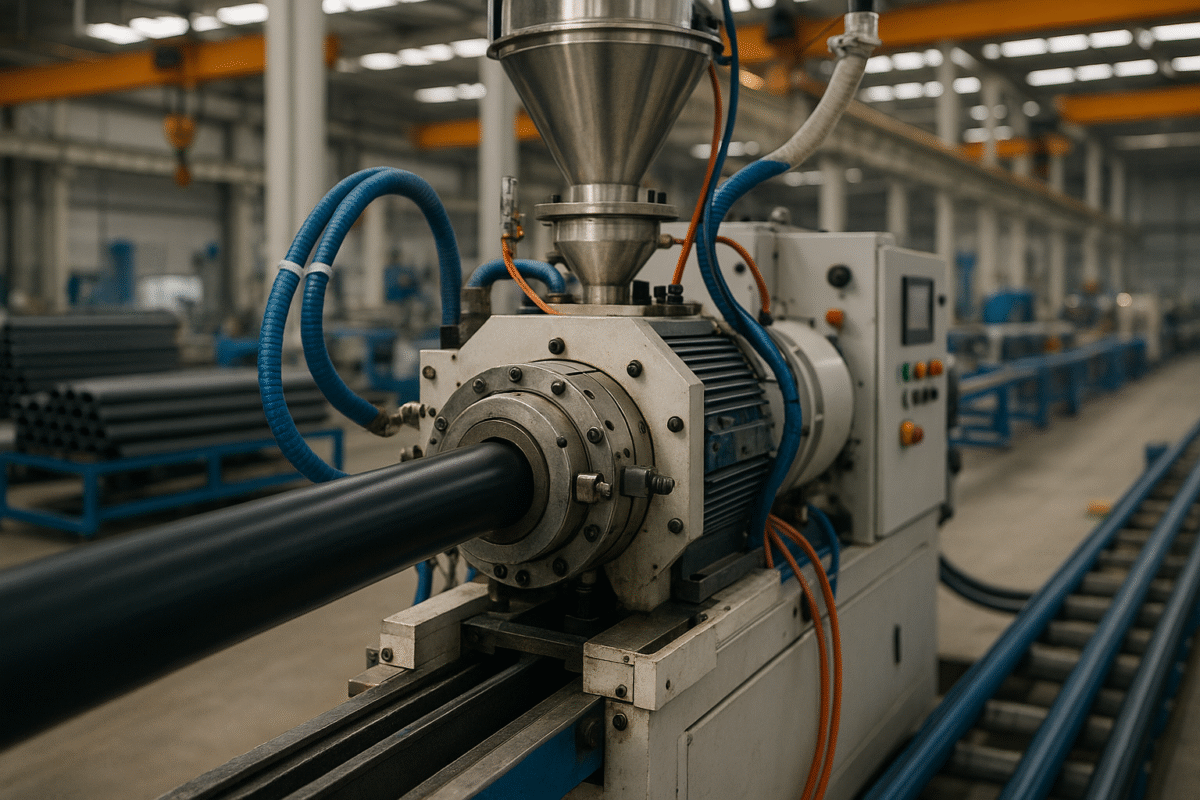

Pipe extrusion is a continuous manufacturing process where raw polymer granules such as PVC, HDPE, PP, or PPR are melted, shaped, cooled, and cut into pipes. The heart of the process is the plastic pipe extrusion machine, which heats and pushes material through a die to form the desired pipe diameter and thickness.

The complete extrusion line consists of several key units: the extruder, die head, calibration system, cooling tanks, haul-off, cutting machine, and stacking or coiling equipment. Together, these components ensure smooth, high-speed production of pipes that meet international standards.

Types of Pipes Produced Through Extrusion

The versatility of pipe extrusion technology makes it useful for multiple industries. In the UAE, it is used to manufacture water supply pipes for residential and commercial plumbing, UPVC and HDPE drainage pipes for sewerage systems, electrical conduit pipes for construction projects, irrigation pipes for agriculture, and heavy-duty industrial pipes for petrochemicals and oil. This adaptability enables manufacturers to cater to diverse markets without requiring multiple production systems.

Why Manufacturing Efficiency Matters in Pipe Production

Challenges in Traditional Manufacturing Processes

Traditional methods of pipe production often suffer from inefficiencies such as high raw material wastage, energy-intensive operations, slower production speeds, and inconsistency in pipe quality. For example, uneven wall thickness or poor surface finish leads to rejections and higher customer dissatisfaction, directly impacting profitability.

Market Pressures Driving Efficiency in UAE

In the UAE, efficiency is not just about cutting costs; it is about staying competitive in a market driven by mega projects and infrastructure expansion. According to a report by Mordor Intelligence, the UAE construction market is expected to grow steadily at 4–5% annually through 2028, creating massive demand for reliable piping solutions. Manufacturers that fail to meet large-scale demand quickly risk losing contracts to competitors. Additionally, government initiatives like UAE Vision 2031 emphasize sustainability and local manufacturing, pushing industries to adopt technologies that ensure both efficiency and environmental compliance.

How Pipe Extrusion Lines Improve Manufacturing Efficiency

High-Volume Continuous Production

One of the most significant advantages of pipe extrusion is its ability to operate continuously. Unlike batch processes, extrusion lines can produce kilometers of pipes without interruption. This high-speed, continuous output enables factories to meet the demands of large construction projects, water supply networks, and industrial applications without delays.

Reduced Material Waste and Cost Savings

Precision is a hallmark of extrusion technology. Advanced plastic pipe extrusion machines ensure exact control over diameter, wall thickness, and material flow, which reduces scrap and wastage. Some modern lines even integrate recycling systems that allow manufacturers to reprocess off-cuts directly back into production. This not only lowers raw material costs—often one of the largest expenses in manufacturing—but also supports sustainable operations.

Energy Efficiency and Automation

Energy costs are a growing concern in the Middle East, where industrial operations consume significant power. Modern extrusion systems are designed with energy efficiency in mind. Optimized heating zones, efficient cooling systems, and intelligent drive motors reduce overall electricity consumption. Additionally, automation plays a transformative role. Real-time monitoring systems track parameters like pressure, temperature, and speed, automatically adjusting to maintain efficiency and avoid downtime. This reduces labor dependency and ensures consistent production even during long shifts.

Consistent Product Quality

Manufacturers know that delivering pipes that meet international standards is non-negotiable. Extrusion lines excel in quality control by maintaining uniform wall thickness, smooth finishes, and consistent diameter across production runs. This eliminates costly variations and ensures compliance with ISO and ASTM standards—an essential requirement for winning large-scale contracts in the UAE’s infrastructure and construction sectors.

Flexibility and Customization in Production

Pipe extrusion lines are highly flexible, allowing manufacturers to quickly switch between different pipe sizes, wall thicknesses, and material compositions. This adaptability helps factories respond quickly to project-specific requirements, whether for large-diameter drainage pipes or smaller PPR pipes for hot and cold water supply. The ability to serve multiple markets with one line improves efficiency and boosts return on investment.

The Role of Technology in Enhancing Extrusion Efficiency

Smart Manufacturing and IoT Integration

Industry 4.0 has made its way into extrusion technology. Smart extrusion lines now come with IoT-enabled sensors that provide real-time data on machine performance. This allows factory managers to optimize production, detect inefficiencies instantly, and implement predictive maintenance before failures occur. Such features reduce downtime and extend machine life.

Automation and Robotics

Automation has replaced many manual operations in pipe extrusion. Automated cutting and stacking systems ensure precise pipe lengths and packaging, reducing errors and minimizing labor needs. Robotics also contributes to material handling and quality checks, freeing human operators to focus on supervision and strategy rather than repetitive tasks.

Multi-Layer Co-Extrusion Technology

Modern pipe extrusion lines also include co-extrusion capabilities, which allow the production of multi-layer pipes. These pipes are stronger, more durable, and capable of handling specialized applications such as high-pressure water supply or chemical transport. Multi-layer technology not only expands market potential but also improves efficiency by producing advanced products on a single line.

Business Benefits of Investing in Efficient Pipe Extrusion Lines

Lower Operational Costs

By reducing material waste, minimizing energy consumption, and lowering labor dependency, efficient extrusion systems cut overall operating costs. Manufacturers can produce more with fewer resources, directly boosting profitability.

Faster Time-to-Market

In the UAE, construction and infrastructure projects often run on tight deadlines. Pipe extrusion lines, with their ability to operate continuously at high speed, help manufacturers meet delivery schedules without compromising on quality. This reliability strengthens client trust and ensures repeat business.

Increased Competitiveness

Locally manufactured pipes produced with extrusion technology give UAE companies an edge over imports. With shorter lead times and lower logistics costs, manufacturers using advanced extrusion machines are better positioned to compete both domestically and in regional export markets across GCC, Africa, and South Asia.

Alignment with Sustainability Goals

Sustainability is no longer optional. Pipe extrusion supports eco-friendly practices by enabling the use of recyclable materials and reducing the carbon footprint of manufacturing. This aligns with the UAE’s sustainability strategies and improves the reputation of manufacturers in a market that values green initiatives.

Key Considerations When Choosing an Extrusion Line

Evaluating Machine Capacity and Output

Manufacturers should assess whether a line’s capacity aligns with their production goals. A mismatch could lead to under-utilization or bottlenecks during peak demand.

Energy Efficiency and Cost of Ownership

When investing in a plastic pipe extrusion machine, the upfront cost is only part of the equation. Decision-makers should evaluate total lifecycle value, including energy consumption, maintenance, and spare parts availability.

Supplier Reliability and After-Sales Support

Partnering with a reliable supplier is crucial. Technical support, operator training, and availability of spare parts can make the difference between a smoothly running production line and costly downtime. UAE manufacturers increasingly prefer suppliers who offer strong local support and quick service response.

The Future of Pipe Extrusion and Manufacturing Efficiency in UAE

Growth Projections for the Pipe Industry in GCC

The demand for plastic pipes in the GCC is projected to grow significantly due to urbanization, infrastructure development, and industrial expansion. Market research estimates that the global plastic pipe market will surpass USD 50 billion by 2030, with the Middle East contributing a substantial share.

Emerging Technologies in Extrusion

AI-driven quality control, real-time defect detection, and integration of renewable energy in extrusion plants are set to define the future of manufacturing. These innovations promise even higher efficiency levels and lower operating costs.

Long-Term Outlook

As the UAE continues to diversify its economy and invest in sustainable infrastructure, extrusion lines will remain a cornerstone of manufacturing. Factories that adopt modern extrusion technology will not only meet present demand but also future-proof their operations against global competition.

Conclusion

Manufacturing efficiency is the backbone of industrial growth, and in the UAE, pipe extrusion has become the key to achieving it. From high-volume production and reduced waste to energy savings and product consistency, extrusion technology addresses the very challenges that manufacturers face today. For decision-makers, the opportunity is clear: investing in advanced pipe extrusion lines is not just about keeping up with demand—it is about staying ahead of the curve. By adopting efficient extrusion systems, UAE manufacturers can lower costs, enhance competitiveness, align with sustainability goals, and strengthen their position in both local and global markets.