Have you ever wondered why some lightweight structures remain stable for decades while others fail under stress? The difference often lies in attachment points for lightweight materials. Whether working on timber framing construction in Australia or exploring modern lightweight methods, choosing the right attachment strategy ensures your build is both durable and safe.

This guide explores the essentials of attachment points, from timber wall framing details to modern adhesive systems. You’ll learn how to choose the right connectors, installation best practices, cost factors, and innovations shaping the future of construction.

What Are Attachment Points?

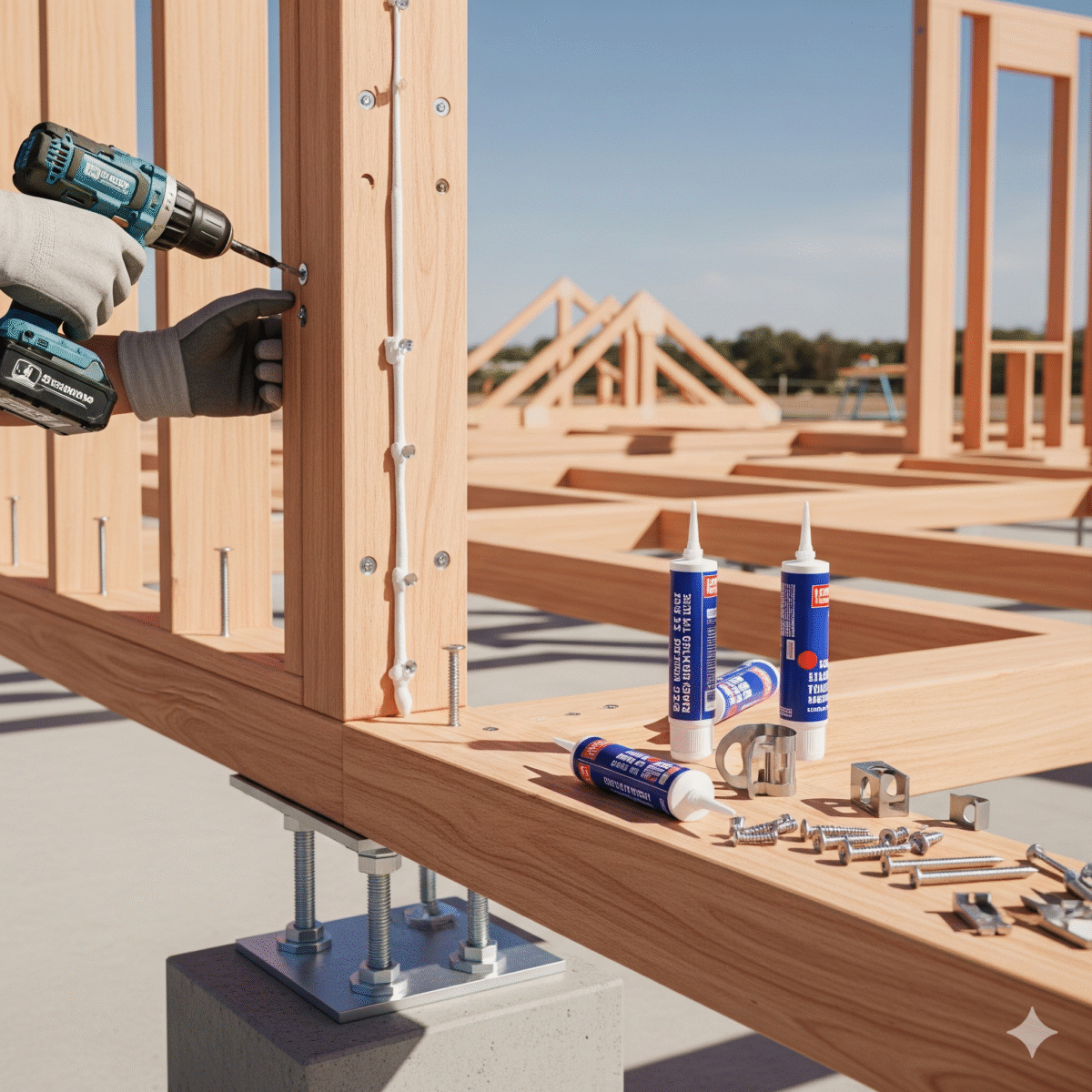

Attachment points are the connections that hold lightweight structures together. In timber wall framing, they determine how studs, beams, and panels transfer loads as a unified system.

Think of them as invisible anchors—without strong attachment points, even high-quality materials won’t perform as intended. Whether you’re working with timber, composites, plastics, or panels, attachment design is crucial for stability and long-term performance.

Why Attachment Points Matter in Lightweight Construction?

- Load Transfer – They distribute both static and dynamic loads, protecting against stress concentrations.

- Durability – Properly chosen points withstand Australia’s harsh climate—heat, humidity, and coastal salt.

- Safety – Reliable connections reduce the risk of structural failures in houses and commercial projects.

Types of Attachment Points

Mechanical Fasteners

- Screws: Excellent holding power in timber studs, ideal for disassembly.

- Nails: Cost-effective and fast, suited for permanent connections.

- Bolts: High-strength solutions for timber frame walls and foundations.

Adhesive Systems

- Structural adhesives: Distribute loads evenly, rivaling mechanical fasteners.

- Epoxies: Great for composites and permanent bonds.

- Double-sided structural tapes: Provide clean, quick panel connections without visible fasteners.

Specialised Fasteners

- Magnetic systems: Ideal for temporary structures.

- Hook-and-loop: Used in fabric and removable panels.

- Snap-fit & click-lock: Perfect for modular timber framing systems where flexibility and speed are vital.

How to Choose the Right Attachment Points?

Match to Material

- Softwoods vs hardwoods: Different screw patterns are required.

- Engineered timber: Needs specially designed fasteners.

Load Requirements

- Consider static loads (weight) and dynamic loads (wind, seismic activity).

- Exceed Australian Standards where possible for extra safety.

Environmental Factors

- Coastal areas: Use corrosion-resistant fasteners.

- Bushfire-prone zones: Choose high-temperature resistant connectors.

- Moisture & temperature changes: Allow for timber expansion and contraction.

Benefits of Proper Attachment

- Structural Stability – Loads spread evenly, preventing local stress failures.

- Cost Efficiency – Fewer callbacks and reduced overengineering save time and money.

- Design Freedom – Modern connection systems allow larger spans, open-plan layouts, and creative structures.

Cost Considerations

- Nails & screws: Low cost per unit, but require labour.

- Structural screws: Higher upfront price but reduce pre-drilling.

- Adhesives: More expensive initially but cut labour time.

Other factors:

- Stainless steel fasteners cost more than galvanised.

- Labour costs rise with complexity.

- Long-term value matters more than upfront price—premium fasteners prevent costly failures later.

Installation Best Practices

Mechanical Fasteners

- Clean, dry, defect-free timber surfaces.

- Pre-drill in hardwoods to prevent splitting.

- Maintain edge distances and spacing per Australian Standards.

Adhesives

- Surfaces must be perfectly prepared—free of dust, grease, or moisture.

- Follow curing time and application thickness guidelines.

- Use temporary supports until full bond strength develops.

Avoid Common Mistakes

- Over-tightening, which crushes timber fibres.

- Under-tightening, leaving loose connections.

- Mixing incompatible materials, causing corrosion.

- Ignoring grain direction, leading to timber splitting.

Maintenance and Longevity

- Regular Inspections: Check for loosening, corrosion, and adhesive delamination.

- Replacement: Use same or better-grade fasteners; avoid removing multiple points at once.

- Preventative Care: Apply protective coatings, allow ventilation, and schedule routine maintenance.

- Upgrades: Renovations provide opportunities to switch to stronger, more efficient fasteners.

Trends and Innovations

Engineered Fasteners

- Self-tapping screws for engineered timber—no pre-drilling required.

- Bi-metal fasteners combine the strength of steel with the corrosion resistance of stainless steel.

Smart Fastening Systems

- Load-sensing fasteners for real-time monitoring.

- Temperature-responsive attachments that adjust tension automatically.

Sustainable Solutions

- Bio-based adhesives made from plant materials.

- Recyclable fasteners for disassembly and reuse.

- Eco-friendly systems supporting sustainable timber framing construction in Australia.

Conclusion: Building Stronger with the Right Attachments

Choosing the right attachment points for lightweight materials is about more than simply holding components together—it’s about safety, durability, and design potential. From timber wall framing in residential builds to advanced modular systems, strong connections ensure structures stand the test of time.

Focus on:

- Matching attachment methods to material and environment.

- Prioritising long-term reliability over short-term cost savings.

- Staying informed about new technologies and sustainable solutions.

With careful planning, installation, and maintenance, your lightweight structures won’t just stand—they’ll thrive for decades.