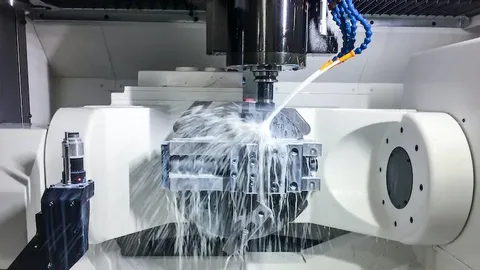

Manufacturing industries are under increasing pressure to deliver precision parts quickly and cost-effectively. As technology advances, traditional machining methods are being replaced with more sophisticated processes to meet growing market demands. One of the most powerful innovations in this space is 5 axis machining, which allows manufacturers to achieve unmatched efficiency and accuracy while significantly boosting productivity.

Unlike traditional 3-axis machines, which move along three directions (X, Y, and Z), 5 axis machining adds two additional axes of rotation. This enables the cutting tool to approach a part from virtually any angle, reducing the need for multiple setups. The result is faster production, higher accuracy, and the ability to create complex geometries that were once considered impossible.

Understanding the Power of 5 Axis Machining

The foundation of 5 axis machining lies in its ability to maneuver a workpiece or the cutting tool across five distinct axes simultaneously. This freedom of movement means that intricate parts, such as turbine blades or medical implants, can be manufactured in a single setup, reducing lead times and minimizing human error. Unlike 3-axis machines, which require constant repositioning, 5 axis machining ensures that critical dimensions are maintained with precision.

This capability translates into improved productivity because the process eliminates secondary operations. Parts that once took days to produce using multiple machines can now be completed in a matter of hours. For industries such as aerospace, automotive, and medical devices—where precision and speed are non-negotiable—5 axis machining provides a clear competitive advantage.

Reducing Setup Times and Increasing Efficiency

One of the primary ways 5 axis machining boosts productivity is by reducing setup times. Traditional machining methods often require parts to be repositioned several times to reach different angles, increasing the risk of inaccuracies. With 5 axis machining, a component can be cut from multiple angles in a single setup, ensuring consistency while saving valuable time.

In addition, this reduction in setups directly contributes to greater efficiency on the shop floor. By minimizing manual intervention, operators can focus on overseeing multiple machines rather than constantly adjusting workpieces. This streamlining of processes not only accelerates production but also reduces labor costs, allowing manufacturers to allocate resources more effectively.

Enhancing Accuracy and Quality of Complex Parts

Complex geometries and intricate designs are increasingly common in modern manufacturing. With 3-axis machines, creating such parts often requires custom fixtures and multiple machining steps, leading to cumulative errors. 5 axis machining eliminates these challenges by allowing the tool to access hard-to-reach surfaces seamlessly, ensuring precision in every cut.

Moreover, the accuracy of 5 axis machining improves overall product quality. Manufacturers can maintain tighter tolerances, reduce scrap rates, and deliver superior parts that meet rigorous industry standards. Whether producing orthopedic implants or aerospace components, this level of precision translates into higher customer satisfaction and fewer costly reworks.

Expanding Design Possibilities for Innovation

One of the most transformative benefits of 5 axis machining is its ability to bring complex design concepts to life. Engineers and product designers are no longer limited by the constraints of traditional machining methods. They can create innovative parts with undercuts, deep cavities, and intricate contours that were once unachievable.

This freedom encourages innovation across industries. For example, in the automotive sector, designers can experiment with lightweight yet strong structures that improve fuel efficiency. In aerospace, intricate turbine blades can be produced with exceptional precision. By removing design limitations, 5 axis machining not only boosts productivity but also accelerates the pace of innovation.

Maximizing Return on Investment (ROI) in Manufacturing

While the initial investment in 5 axis machining equipment can be significant, the long-term benefits far outweigh the costs. The combination of reduced setup times, higher accuracy, and expanded design capabilities translates into faster production cycles and increased profitability. Manufacturers that adopt this technology often see a rapid return on investment.

Additionally, the ability to consolidate multiple machining processes into one setup reduces the need for additional machinery, labor, and maintenance. This consolidation lowers operational expenses while increasing throughput. Over time, businesses that embrace 5 axis machining not only improve productivity but also gain a strong competitive edge in the global market.

Conclusion

In today’s fast-paced manufacturing environment, productivity and precision are critical to success. Advanced 5 axis machining capabilities empower manufacturers to achieve both by reducing setup times, enhancing accuracy, expanding design possibilities, and maximizing efficiency. By investing in this technology, companies can position themselves at the forefront of innovation while ensuring long-term profitability.

As industries continue to evolve, the demand for complex and high-quality parts will only grow. 5 axis machining is not just a tool for meeting this demand—it is a strategic asset that redefines what is possible in modern manufacturing.