Why Choosing the Right AC Drain Pipe Size Matters

The AC drain pipe is one of the most overlooked components of any HVAC system, yet it plays a critical role in keeping your home or office safe from water damage. This pipe is responsible for carrying the condensate water produced by the evaporator coil safely outside or to a designated drainage point. While it may seem minor, selecting the correct diameter and material can significantly influence the efficiency and longevity of your AC system.

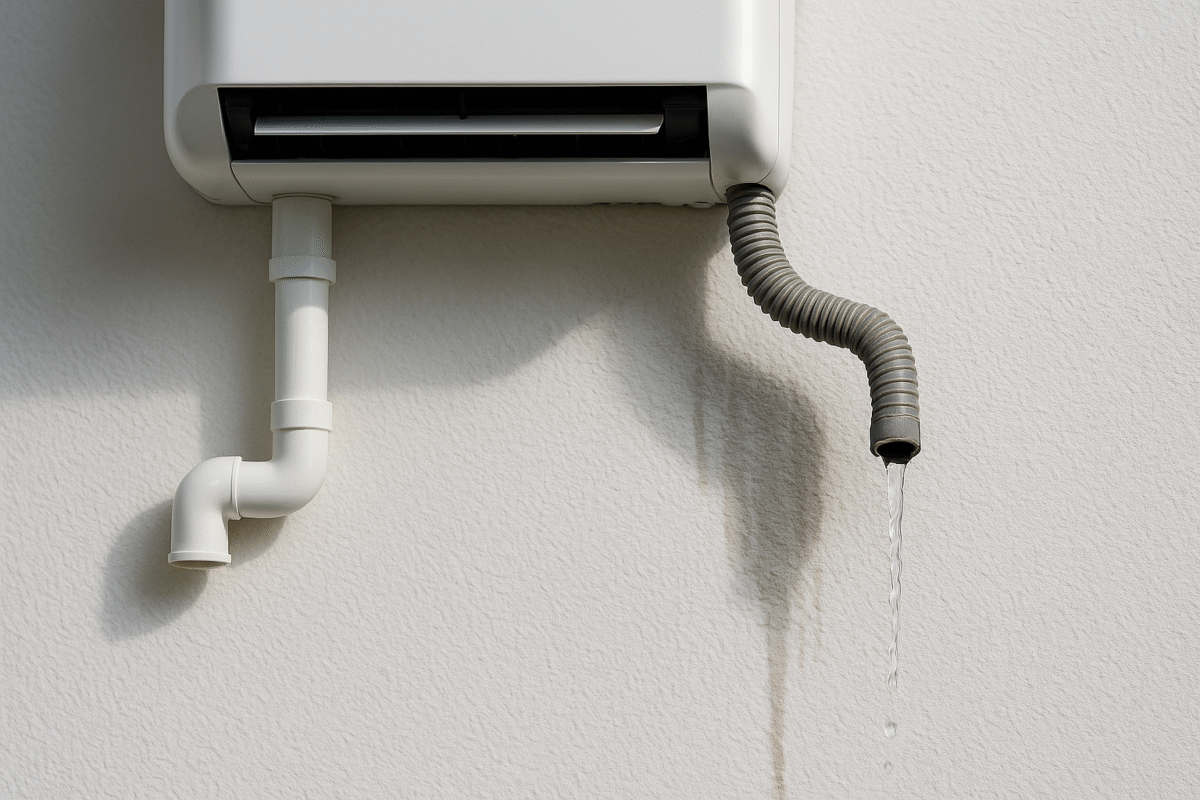

Using the wrong size can lead to frequent clogs, water overflow, and even mold growth. According to the U.S. Department of Energy, clogged or poorly installed AC drain lines reduce HVAC efficiency by up to 15%, causing higher energy bills and unnecessary strain on the system. For residents in high-humidity regions, such as Pakistan, a properly sized AC drain pipe in Pakistan ensures continuous drainage during peak usage months, especially during the scorching summer.

Understanding the right size and installation techniques can save homeowners and HVAC technicians both time and money, reducing the risk of repairs caused by water-related damage.

How AC Drain Pipes Work

The function of an AC drain pipe might seem straightforward, but the mechanics behind proper drainage are essential for system performance. As your AC cools the air, moisture condenses on the evaporator coil. This water collects in the drain pan and exits through the AC drain pipe. If the pipe is too narrow, water will drain slowly or stagnate, encouraging algae and mold growth. If it’s too wide, it may be unnecessarily expensive and more challenging to install without proper support.

The slope or pitch of the pipe works in tandem with the pipe size to maintain smooth drainage. Ideally, the pipe should have a downward slope of at least 1/4 inch per foot. Combining proper sizing with slope ensures condensate flows freely, preventing water from pooling in the pan or along the pipe run.

A well-functioning AC drain line keeps your system running efficiently while avoiding hidden dangers such as leaks, mold development, and structural damage in ceilings or walls.

Standard AC Drain Pipe Sizes and Materials

When selecting an AC drain pipe, understanding standard sizes and materials is crucial. Residential systems typically use diameters between 3/4 inch and 1 inch, while larger commercial units may require 1.25-inch pipes to handle increased condensate.

The most common materials include PVC, CPVC, and flexible tubing. PVC is durable, resistant to corrosion, and widely available. CPVC offers slightly higher heat resistance, suitable for systems exposed to hotter condensate or outdoor conditions. Flexible tubing is easier to install in tight spaces, but it is less durable and prone to kinking, which can obstruct water flow.

AC system capacity also influences pipe selection. A 1–2 ton system often requires a 3/4 inch PVC pipe, whereas a 2–3 ton system usually needs a 1-inch pipe. In areas like Pakistan, where high temperatures and humidity increase condensate production, these sizing standards help ensure reliable drainage.

Pricing varies based on material and diameter. On average, a 3/4 inch PVC pipe costs between PKR 150–300 per meter in Pakistan. Choosing the right size upfront is more cost-effective than dealing with repeated clogs or water damage.

Factors Affecting the Choice of AC Drain Pipe Size

Several factors influence the proper sizing of your AC drain pipe. The first is the system’s capacity or tonnage. Larger AC units produce more condensate, requiring a wider pipe to avoid overflow. For instance, a 5-ton commercial system generates considerably more water than a 1.5-ton residential unit, demanding a proportionally larger drain line.

The distance and layout of the drain line also matter. Longer horizontal runs or vertical lifts may require slightly larger pipes to maintain the flow rate. Slope or pitch is equally crucial; even a correctly sized pipe will fail if water pools in low spots.

Climatic conditions are another consideration. High-humidity regions like Pakistan naturally produce more condensate, necessitating pipes that can handle peak water volumes. Additionally, the material and durability of the pipe play a role. Smooth PVC surfaces reduce friction and the chance of algae buildup, while flexible tubing may be more prone to blockages over time.

Lastly, consider whether multiple AC units share a single line. Multi-unit systems require larger diameters to accommodate the combined condensate flow, preventing backups and potential water damage.

Calculating the Correct AC Drain Pipe Size

Calculating the right AC drain pipe size ensures your system handles maximum condensate flow without clogging. One simple approach is to consider the AC unit’s tonnage and typical condensate production. A 2-ton system generally produces 2–3 gallons of water per hour, which corresponds to a 3/4 inch pipe diameter.

Many HVAC manufacturers provide condensate flow rate charts, allowing homeowners and technicians to select a pipe that accommodates peak output. When sizing a pipe, it’s also wise to add a safety factor. For example, slightly increasing the diameter can future-proof your system against higher humidity conditions or increased AC usage.

Local building codes may dictate minimum pipe diameters for residential or commercial systems, so checking compliance is essential. By combining manufacturer guidance, local regulations, and safety margins, you can select a pipe that prevents overflow, mold growth, and maintenance headaches.

Common Mistakes When Choosing AC Drain Pipe Size

Several mistakes commonly occur during AC drain pipe installation. A frequent error is selecting a pipe that’s too small. Narrow pipes clog more easily, resulting in water overflow and damage to floors, ceilings, or walls. On the other hand, oversizing unnecessarily increases costs and installation difficulty without providing a significant benefit.

Ignoring slope is another common issue. Even a correctly sized pipe can fail if improperly pitched, leading to stagnant water and increased maintenance. Failing to include maintenance access points, such as cleanout tees, also complicates cleaning and flushing, allowing minor clogs to escalate into significant problems.

Using inappropriate materials is another error. For example, flexible tubing may be convenient but can kink or deteriorate faster in humid conditions. In Pakistan, a 3-ton unit using a 5/8 inch flexible line experienced repeated leaks until it was replaced with a properly sized PVC pipe. Such examples underscore the importance of considering all factors, from material to slope and capacity.

Installation Tips for Optimal AC Drain Pipe Performance

Proper installation is as important as correct sizing. Ensure a minimum downward slope of 1/4 inch per foot for smooth drainage. Rigid PVC pipes should be connected using PVC cement, while flexible tubing requires secure clamps to prevent sagging. Avoid sharp bends that can impede water flow.

Including a cleanout tee every 5–10 feet allows easy access for flushing or clearing clogs. Insulating the line in humid climates helps prevent condensation from forming on the exterior of the pipe. Before powering the AC, test the drainage system by pouring water into the drain pan and confirming smooth flow through the pipe.

Following these installation tips prolongs the life of your AC drain pipe, reduces maintenance frequency, and prevents water-related damage.

Maintenance Tips to Ensure AC Drain Pipe Efficiency

Maintenance ensures the long-term performance of your AC drain pipe. Flushing the line monthly with distilled white vinegar or a mild solution prevents algae and mold buildup. Using a wet/dry vacuum on the outdoor end removes sediment and debris that could obstruct flow.

Regular inspections of the slope and joints detect leaks or sagging early, preventing serious problems. Annual professional inspections are recommended to check for hidden blockages, inspect condensate pumps, and ensure proper pipe alignment.

Proper sizing not only improves drainage efficiency but also makes maintenance simpler and more effective. A correctly sized, well-maintained pipe reduces the likelihood of costly repairs or emergency service calls.

Conclusion

Choosing the right AC drain pipe size is critical for maintaining HVAC efficiency and preventing water damage. By considering system capacity, pipe length, slope, material, and local climate conditions, homeowners and technicians can select a pipe that performs reliably year-round. Proper installation, routine maintenance, and adherence to manufacturer guidelines further ensure smooth operation.

For those searching for AC drain pipe in Pakistan, understanding these principles helps make informed decisions regarding installation quality and long-term durability. Considering the AC drain pipe price in Pakistan in combination with proper sizing ensures both efficiency and cost-effectiveness, reducing the risk of clogs, overflows, and structural damage.

FAQs

Q: What is the standard AC drain pipe size for a 1-ton AC?

Typically, a 3/4 inch PVC pipe is sufficient for 1-ton AC units, though manufacturer guidelines should be followed for best results.

Q: Can I use flexible tubing instead of PVC for AC drain lines?

Flexible tubing works for short runs but is less durable than PVC. PVC is recommended for long-term reliability and minimal clogging.

Q: How does AC drain pipe size affect clogs?

A pipe that is too small will clog frequently, causing water overflow and potential damage to ceilings, walls, and floors.

Q: How much does an AC drain pipe cost in Pakistan?

Prices vary by diameter and material. A 3/4 inch PVC pipe typically costs between PKR 150–300 per meter, with larger pipes or premium materials costing more.

Join our community and connect with like-minded people.